Bonding a corrugated stainless steel tubing (CSST) gas line is an essential safety measure to protect your home and its occupants. Proper bonding reduces the risk of damage from electrical surges, such as those caused by lightning strikes, ensuring the safe operation of the gas system.

This guide on how to bond csst gas line will walk you through the basics of bonding a CSST gas line, highlighting the tools required and the steps to follow to meet safety standards and regulations.

What is the CSST gas line?

Before we dive into the bonding process, it’s important to understand what a CSST gas line is. CSST is a type of flexible piping used for natural gas and propane distribution. It is a popular alternative to traditional black iron or steel pipes due to its flexibility and ease of installation.

CSST is typically made of corrugated stainless steel tubes coated with a layer of polyethylene. This coating provides protection against corrosion, making it durable and suitable for use in various environments. CSST is commonly used in residential and commercial buildings for gas supply to appliances such as stoves, water heaters, and furnaces.

Why Do You Need to Bond a CSST Gas Line?

Bonding a CSST gas line is essential for safety reasons. While the metal tubing itself is conductive, the plastic coating can act as an insulator, creating electrical resistance. This resistance can lead to a buildup of electrical charges within the CSST, making it more susceptible to damage from lightning strikes or other electrical surges.

If a lightning strike or power surge occurs near a CSST gas line that is not bonded, it could cause an arc between the gas piping and an electrically conductive object, such as a metal appliance or water pipe. This could result in a fire or explosion, causing significant damage to your home and potentially endangering occupants.

To prevent this scenario, bonding connects the CSST gas line to the home’s grounding system, providing a safe path for any electrical charges to dissipate. Properly bonded CSST reduces the risk of fires and explosions, ensuring the safe operation of your gas system.

Tools Required for Bonding a CSST Gas Line

Bonding a CSST gas line is relatively simple and requires minimal tools. Here are the essential tools you will need to complete the bonding process:

Wrench or Pliers:

To tighten connections on the bonding clamp and grounding electrode conductor.

Wire Brush:

To clean the surface of the CSST and grounding electrode.

Emery Cloth or Sandpaper:

Remove any corrosion from metal surfaces before making connections.

Bonding Clamp:

A special type of clamp is used to connect the CSST gas line to the grounding electrode.

Grounding Electrode:

A metal rod or plate buried in the ground outside your home that serves as a connection to the earth’s electrical potential.

Grounding Electrode Conductor:

A wire is used to connect the bonding clamp and grounding electrode.

7 Steps on How to Bond CSST Gas Line

Step 1: Prepare the Area

Begin by ensuring the area around the CSST gas line is safe and accessible. Turn off the gas supply to eliminate any potential hazards during the bonding process. Inspect the gas line and surrounding area, making sure there are no damage, corrosion, or leaks that could compromise safety. Clear any debris or obstacles that could interfere with your work, and ensure sufficient lighting to help you see all necessary components clearly.

If needed, use the wire brush or emery cloth to clean the surfaces of the CSST and nearby metal connections, removing any dirt or corrosion to ensure a solid bond. Always wear safety gloves and eye protection during this process to reduce the risk of injury.

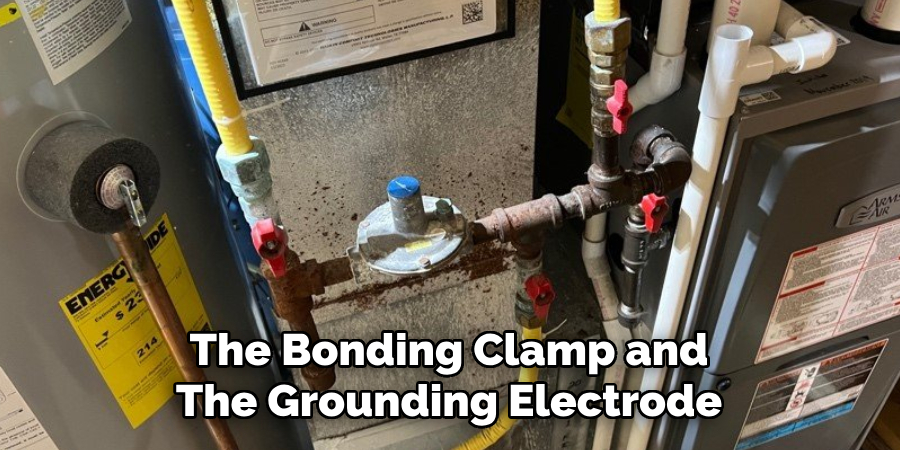

Step 2: Locate the Bonding Clamp and Grounding Electrode

Identify the bonding clamp and the grounding electrode that will be used in the bonding process. The bonding clamp should be specifically designed for CSST gas lines and must be compatible with the size of the tubing. It typically attaches securely around the metal portion of the CSST. Ensure that the bonding clamp is UL-listed or meets your local code requirements for safety and reliability.

Next, locate the grounding electrode for your home. This is usually a metal rod, pipe, or plate buried in the ground near your house or connected to the home’s electrical panel. The grounding electrode provides a direct path to the earth, allowing electrical charges to dissipate safely. Verify that the grounding electrode is accessible and in good condition. If there are any signs of excessive corrosion or damage, consult a professional to replace or repair it before proceeding with the bonding process.

Step 3: Measure the Length of the Grounding Electrode Conductor

Carefully measure the distance between the bonding clamp and the grounding electrode to determine how much grounding electrode conductor wire you will need. Add a few extra inches to ensure there is enough slack to make connections. Cut the grounding electrode conductor to that length using a wire cutter or pliers.

You can use either copper or aluminum grounding electrode conductors, but make sure they are the appropriate gauge for your particular installation. Refer to your local code requirements for specific recommendations on conductor size.

Step 4: Install the Bonding Clamp

Place the bonding clamp around the metal portion of the CSST gas line and secure it by tightening it with a wrench or pliers. The clamp should be tight enough to ensure good contact with the pipe but not so tight as to cause damage. Make sure that no plastic coating is in direct contact with the clamp.

Otherwise, the bonding process will be ineffective.

Step 5: Connect the Grounding Electrode Conductor

Strip off about half an inch of insulation from both ends of the grounding electrode conductor wire using a wire stripper or knife. On one end, wrap the bare wire around the bolt on the bonding clamp and tighten securely with a wrench or pliers.

On the other end, connect to the grounding electrode by wrapping it around any available connection point and securing it tightly. If there is no such point, consult a professional for advice on how to properly attach it.

Step 6: Test Your Work

After completing the connections, it is crucial to test the bonding to ensure it has been done correctly and safely. Begin by visually inspecting all connections to confirm that the bonding clamp is securely attached to the CSST gas line and that the grounding electrode conductor is firmly connected to both the bonding clamp and the grounding electrode. Check for any loose connections or exposed wire that could compromise the safety or effectiveness of the bonding.

Once the visual inspection is complete, a multimeter will be used to test the electrical continuity of the bonding path. Set the multimeter to the continuity testing mode, then place one probe on the CSST gas line and the other on the grounding electrode. A successful test will show continuity, confirming that the electrical path is intact. If you do not achieve continuity, recheck and tighten all connections before testing again. If the issue persists, consult a professional for further assistance.

Step 7: Restore the Gas Supply and Recheck

Once you have verified the bonding process and confirmed electrical continuity, it is time to restore the gas supply. Begin by carefully turning the gas valve back on, ensuring it is fully open. Watch for any signs of gas leaks, such as unusual smells or hissing sounds, and be prepared to shut off the gas immediately if needed.

After restoring the gas supply, perform a final inspection of the CSST gas line and all connections. Ensure that the bonding clamp and grounding electrode conductor are still secure and that the gas line itself shows no signs of damage, stress, or leaks. For added safety, consider using a gas leak detector or applying soapy water to the connections to check for any leakage. If bubbles form, this indicates a leak that must be addressed before further use.

By following these steps on how to bond the CST gas line and taking the necessary precautions, you can safely bond your CSST gas line for added protection and peace of mind. Remember to always consult your local codes and regulations for specific requirements and to seek professional assistance if needed. Regularly check and maintain your gas line to ensure continued safety and efficiency in your home. Happy bonding!

Additional Tips for Maintaining a Safe Gas Line

While proper bonding is essential, there are other steps you can take to maintain the safety and functionality of your gas line:

- Regularly inspect the CSST gas line for any signs of damage or wear, such as kinks, dents, or corrosion. Address any issues promptly and seek professional assistance if needed.

- Avoid using sharp tools or objects near the gas line that could potentially puncture or damage it.

- Keep the area around your gas line clear of debris, clutter, and any potential hazards to prevent accidents and allow for easy access in case of emergencies.

- Educate everyone in your household about gas safety, including how to detect a leak and what to do in case of an emergency.

By following these tips on how to bond csst gas line and staying informed about proper bonding techniques for CSST gas lines, you can ensure the continued safety and functionality of your home’s gas supply.

Conclusion

Properly bonding a CSST gas line is a critical step in safeguarding your home from potential electrical hazards. By ensuring the gas line is correctly bonded to the grounding system, you reduce the risk of electrical arcing that could lead to damage or fire. Following the outlined steps on how to bond csst gas line and adhering to local building codes helps ensure the process is done safely and effectively.

Always prioritize safety by inspecting your work thoroughly, testing for continuity, and consulting professionals when in doubt. Regular maintenance and vigilance go a long way toward protecting your household, giving you confidence in the reliability of your gas system. Taking these precautions will not only comply with regulations but also provide long-term peace of mind.

About the Author

Adrian Green is a passionate woodworking enthusiast who has dedicated his life to the craft of woodworking. From his early days working alongside his father in the family woodworking shop, Adrian has honed his skills and developed a deep love for creating beautiful, functional pieces with his hands. As the voice behind The Woodenify Blog, he shares his knowledge, tips, and inspiration with fellow woodworkers of all skill levels, helping them build confidence in their abilities while learning new techniques.

Professional Focus

- Specializes in DIY woodworking projects, from furniture making to home décor.

- Provides step-by-step guides, tips, and practical tutorials for woodworkers at any skill level.

- Focused on empowering readers with confidence and knowledge through easy-to-follow instructions and hands-on techniques.

- Passionate about building a community where makers can share, learn, and grow together in the world of woodworking.

Education History

University of Craft and Design – Bachelor of Fine Arts (BFA) in Woodworking and Furniture Design

Woodworking Apprenticeships – Gained extensive hands-on experience through various workshops and mentorships with seasoned craftsmen, refining carpentry and furniture-making skills.

Expertise

- DIY woodworking, carpentry, furniture making, and home décor projects.

- Creating clear, accessible tutorials and guides for beginner to advanced woodworkers.

- Helping readers experience the satisfaction and fulfillment of turning raw materials into stunning finished products.