A sump pump is a vital device designed to prevent basement flooding by effectively removing water that accumulates in a sump pit, typically located in the lowest part of a basement or crawl space. It acts as a protective measure against water damage caused by heavy rains, melting snow, or rising groundwater levels. However, like any mechanical system, a sump pump can malfunction or fail over time.

Recognizing the early signs of a problem is crucial in avoiding costly repairs and significant water damage to your home. This article aims to guide homeowners on how to know if sump pump is broken or malfunctioning. By identifying issues early and addressing them promptly, you can ensure your sump pump continues to safeguard your home and maintain peace of mind.

Understanding How a Sump Pump Works

A sump pump is an essential device designed to protect your home from water damage by removing excess water from basements or crawl spaces. Its primary function is to collect water that accumulates in a specially designed basin, known as the sump pit, and pump it away from your home to a safe location, such as a drainage system or a storm drain.

Basic Components of a Sump Pump

A typical sump pump consists of four main components:

- Basin: The pit or container where water accumulates before being pumped out.

- Pump: The core part of the system that moves water from the basin to the discharge outlet.

- Float Switch: A sensor that detects the water level in the basin and activates the pump when necessary.

- Discharge Pipe: The pipe is responsible for transporting the water away from the house to prevent flooding.

Types of Sump Pumps

There are two primary types of sump pumps:

- Pedestal Pump: The motor is mounted above the floor, making it easier to access and maintain.

- Submersible Pump: The motor is located inside the sump pit, fully submerged in water, which allows it to operate more quietly; however, this can make repairs more challenging.

Importance of Regular Maintenance

Regular maintenance is vital to ensure your sump pump remains functional and reliable during times of heavy rain or flooding. Routine checks help identify potential issues, such as clogs or a malfunctioning float switch, before they lead to failure. A well-maintained sump pump provides peace of mind by safeguarding your home from water damage year-round.

Common Causes of Sump Pump Failure

Power Issues

One of the most common reasons for sump pump failure is power loss. Power outages during severe storms can render your sump pump useless when you need it the most. Additionally, tripped circuit breakers can interrupt operation unexpectedly. To mitigate this risk, consider installing a battery backup system or a generator to ensure your pump remains operational during emergencies.

Mechanical Failures

Mechanical problems such as motor burnout, worn bearings, or clogged impellers can significantly impact the functionality of your sump pump. Over time, wear and tear from consistent use can cause components to fail. Regular inspections and prompt replacement of damaged parts can help maintain the efficiency and longevity of your sump pump.

Float Switch Problems

The float switch is a critical component that activates the sump pump when water levels rise. A stuck or broken float switch can prevent the pump from turning on or cause it to run continuously, leading to premature wear. Ensure the float moves freely during maintenance to avoid these issues.

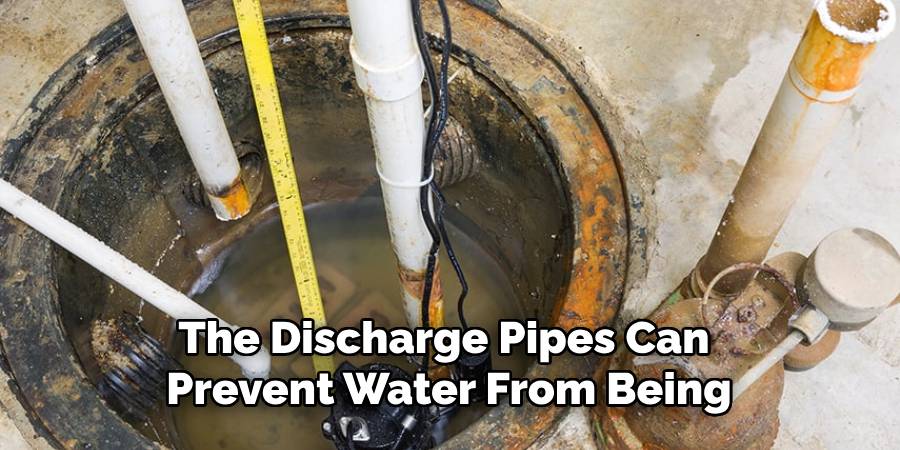

Blocked or Frozen Discharge Pipes

Obstructions, such as debris or ice, in the discharge pipes can prevent water from being effectively removed from the sump pit. This can result in water backing up into your home. Installing a discharge line protector and ensuring proper pipe insulation can help prevent blockages and freezing in colder months.

Poor Installation or Improper Sizing

Installing a sump pump that is incorrectly sized or improperly positioned can limit its effectiveness. A pump too small for your needs may struggle to handle large volumes of water, while poor installation can lead to operational inefficiencies. Always consult a professional to ensure your sump pump is properly sized and installed for optimal performance.

How to Know if Sump Pump is Broken: Signs That Your Sump Pump Might Be Broken

Recognizing the warning signs of a faulty sump pump is crucial to prevent water damage and maintain the safety of your home. Below are common indicators that it might be time to repair or replace your sump pump:

Pump Not Turning On

If your sump pump fails to activate when the water level rises, this could be a clear sign of a malfunction. This issue may stem from electrical problems, a stuck float switch, or internal damage to the pump mechanism. Inspecting the power supply and float switch can help pinpoint the root cause.

Continuous Running

A sump pump that runs nonstop without shutting off could be experiencing a stuck switch or an issue with the float mechanism. Over time, this constant operation can lead to wear and tear, reducing the pump’s lifespan and potentially causing it to fail during critical moments.

Unusual Noises

Grinding, rattling, or humming noises coming from your sump pump are signs that something is wrong. These sounds might suggest worn-out components, debris stuck inside the pump, or even motor failure. Addressing these noises promptly can avoid further damage.

Water Backup or Flooding

Water pooling in your sump pit or basement despite the pump being active is a major red flag. This could indicate a clogged discharge line, a pump that is too weak for the water volume, or a complete failure of the unit to operate as intended.

Frequent Cycling

A pump that turns on and off rapidly or too frequently may indicate a float switch that needs adjustment, oversensitivity, or issues with the basin alignment. Continuous cycling places unnecessary strain on the motor and increases energy use, leading to a higher risk of breakdown.

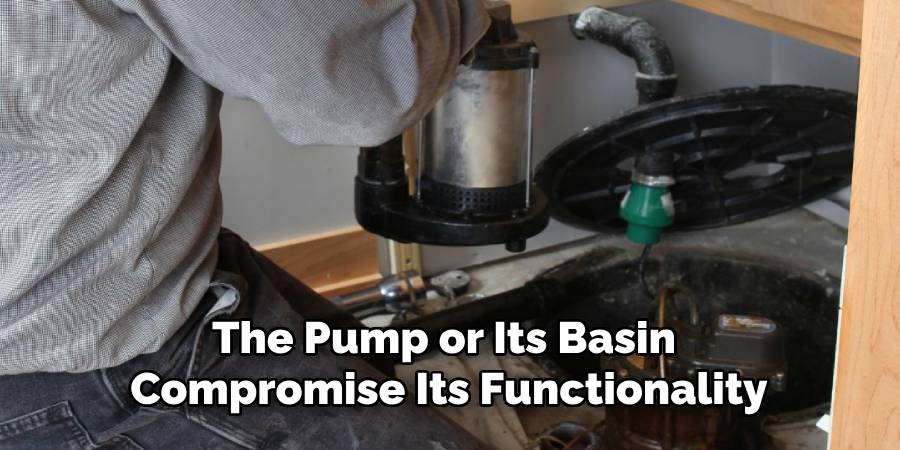

Visible Damage or Corrosion

Rust, cracks, or leaks in the pump or its basin compromise its functionality and durability. Regular inspections for physical damage or signs of corrosion can prevent further deterioration and ensure your sump pump operates efficiently.

How to Test Your Sump Pump

Regular testing of your sump pump ensures it remains in good working condition, especially during heavy rainfall or potential flooding. Follow these steps to perform a thorough check:

Manual Test

To manually test your sump pump, begin by pouring water into the sump pit. The water level should rise, triggering the pump to start automatically. Observe whether the pump effectively removes the water from the pit. If it struggles or fails to activate, further troubleshooting may be necessary.

Checking the Float Switch

The float switch is a crucial component of the sump pump, as it signals the pump to turn on and off based on the water level. Ensure the float moves freely without obstruction and activates the pump appropriately when the water level rises. Sticking or misaligned floats can prevent proper operation.

Inspecting the Power Supply

Verify that the pump is connected to a functioning power outlet. Inspect all cords for damage and ensure circuit breakers aren’t tripped. Without reliable power, the sump pump cannot operate when needed most.

Examining the Discharge Pipe

Examine the discharge pipe for any blockages, leaks, or signs of freezing. Obstructions or ruptures can prevent water from being appropriately expelled, leading to water damage or pump overuse.

Professional Inspection

While regular homeowner testing is necessary, there are times when professional help is required. If you detect persistent issues or suspect severe damage, consult a plumber or technician for a detailed assessment and maintenance to protect your home effectively.

Troubleshooting Common Problems

Resetting the Pump

If your sump pump is not functioning correctly, resetting it might resolve the issue. First, check if your pump is equipped with a reset button. If so, press and hold it for a few seconds to restart the system. If there is no reset button, you can unplug the pump from the power source, wait for approximately 30 seconds, and then plug it back in. This process can help reset the pump’s internal mechanisms and restore normal operation.

Cleaning the Pump and Pit

Debris and sludge are common reasons sump pumps fail. To clean the pump and pit, first disconnect the pump from the power source for safety. Remove the pump and clear away any visible debris or mud from its surface and intake screen. Use a wet-dry vacuum to clean the pit, ensuring proper drainage and reducing the risk of clogs. Reassemble and test the pump after cleaning.

Replacing the Float Switch

A faulty float switch can impede pump operation. To replace it, turn off the power, locate the switch, and remove the damaged part. Install the new switch according to the manufacturer’s instructions, making sure it is properly connected and positioned.

Unclogging the Discharge Pipe

If the discharge pipe is clogged, first inspect the pipe for visible blockages. Use a plumber’s snake or garden hose to clear the obstruction gently. Avoid using harsh chemicals to prevent pipe damage. After clearing the blockage, flush the pipe with water to ensure it is fully unclogged.

When to Replace Your Sump Pump

Signs That Repair Is Not Enough

While repairs can extend the life of your sump pump, there are times when replacement is the better option. One key indicator is frequent breakdowns, which can signal that the pump is nearing the end of its lifespan. Constant malfunctions not only cause inconvenience but also increase the risk of water damage in your basement. Additionally, if your sump pump is over 7-10 years old, it may be less efficient and more prone to failure, even with regular maintenance. Age and wear often reduce its ability to handle heavy workloads, leaving your home vulnerable during periods of heavy rain or flooding.

Benefits of Upgrading to a Newer, More Efficient Model

Upgrading to a newer sump pump model offers several advantages. Modern pumps are generally more energy-efficient, saving you money on power costs while providing better protection for your home. New models often feature updated components, including smarter sensors, quieter operation, and enhanced durability to handle higher water volumes. An updated system ensures peace of mind, especially during extreme weather conditions.

Considering a Battery Backup System

Power outages during storms can render your sump pump useless, leading to potential flooding. Adding a battery backup system to your sump pump ensures it will continue to function even during electrical failures. This backup protection can be a lifesaver, giving you extra time to safeguard your property and providing an added layer of security for your home.

Preventive Maintenance Tips

Regular Inspection and Testing

Inspect and test your sump pump periodically to ensure it is in proper working condition. Pour a bucket of water into the sump pit to check if the pump activates and efficiently removes water. This simple test can help identify issues before they escalate.

Keeping the Sump Pit Clean

Ensure the sump pit is clean and free of debris, as clogs can disrupt the pump’s performance. Regularly remove dirt, mud, or any obstructions that might block the pump intake or impeller. This helps maintain optimal functionality and prolongs the system’s lifespan.

Ensuring Proper Discharge Line Installation

Verify that the discharge line is securely installed and sloped correctly to ensure proper water flow. Protect the line against freezing by insulating it or installing a frost-free outlet to prevent blockages during colder months.

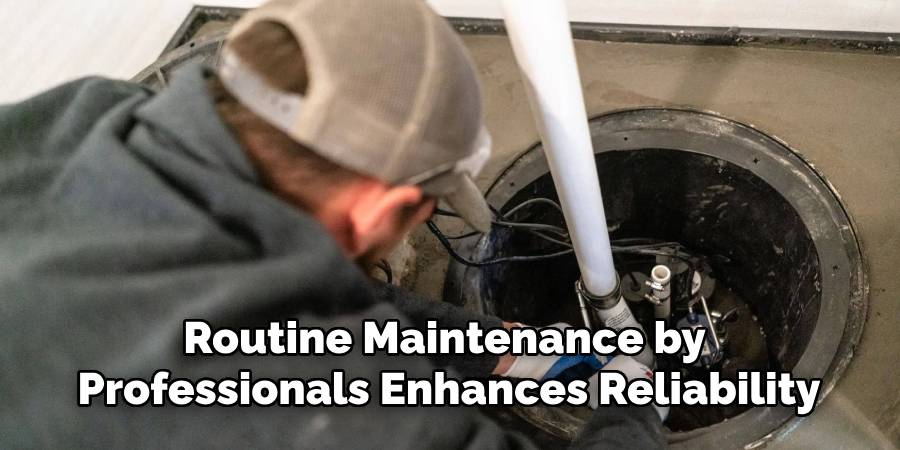

Scheduling Professional Maintenance Annually

Hire a professional to inspect and service your sump pump annually. Trained experts can check for wear, replace faulty parts, and ensure the system operates efficiently. Routine maintenance by professionals enhances reliability and minimizes the risk of failure during critical moments.

Conclusion

Recognizing key signs of sump pump failure is essential to protecting your home from water damage. Common indicators include unusual noises, excessive vibrations, or failure to activate during heavy rainfall. To test the system, pour water into the sump pit to see if the pump starts automatically and efficiently discharges water. Knowing how to know if sump pump is broken enables timely action, preventing costly repairs and damage. Regular maintenance, whether by DIY checks or professional servicing, ensures your sump pump remains in optimal condition, offering peace of mind and safeguarding your home even during severe weather conditions.

About the Author

Adrian Green is a passionate woodworking enthusiast who has dedicated his life to the craft of woodworking. From his early days working alongside his father in the family woodworking shop, Adrian has honed his skills and developed a deep love for creating beautiful, functional pieces with his hands. As the voice behind The Woodenify Blog, he shares his knowledge, tips, and inspiration with fellow woodworkers of all skill levels, helping them build confidence in their abilities while learning new techniques.

Professional Focus

- Specializes in DIY woodworking projects, from furniture making to home décor.

- Provides step-by-step guides, tips, and practical tutorials for woodworkers at any skill level.

- Focused on empowering readers with confidence and knowledge through easy-to-follow instructions and hands-on techniques.

- Passionate about building a community where makers can share, learn, and grow together in the world of woodworking.

Education History

University of Craft and Design – Bachelor of Fine Arts (BFA) in Woodworking and Furniture Design

Woodworking Apprenticeships – Gained extensive hands-on experience through various workshops and mentorships with seasoned craftsmen, refining carpentry and furniture-making skills.

Expertise

- DIY woodworking, carpentry, furniture making, and home décor projects.

- Creating clear, accessible tutorials and guides for beginner to advanced woodworkers.

- Helping readers experience the satisfaction and fulfillment of turning raw materials into stunning finished products.